Arnotts nearly 300000 square foot manufacturing plant is located in Merritt Island on Floridas Space Coast. Conventional vibratory feeders use rubber or spring shock absorbers which allow movement of the drive in all directions resulting in rotational motion.

A Dmaic Approach For Process Capability Improvement An Engine Crankshaft Manufacturing Process Springerlink

P4 Series For Rechargeable Battery Manufacturing Process Adjustable Shock Absorber Fck P4 Component Products Ckd Corporation

3d Printed Shock Absorber With High Degree Of Functionality Covestro Ag

Is the global industry leader in manufacturing quality aftermarket replacement air suspension products and accessories.

Shock absorber manufacturing process. If you dont have a lot of hauling and towing to do and you dont have a big family that you need to drive around the Ford Ranger might be just the truck for you. We are a complete solutions provider for aluminium die-casting braking systems suspension and transmission products. These special separators serve as a shock absorber to the battery.

Each Dobinsons shock absorber is designed specifically for the vehicle and application and is designed to perform best when matched with. A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehiclesOriginally called a laminated or carriage spring and sometimes referred to as a semi-elliptical spring elliptical spring or cart spring it is one of the oldest forms of springing appearing on carriages in France in the mid-17th century in the form of the two-part elbow spring as the illustrated. Not everyone wants a big truck.

Our engineers got under the skin of some of the most iconic vehicles on the road to ensure that we can provide our customers with adjustable upgrade dampers which greatly inprove the handling and roadholding of their cars instantly enhancing their. Cold extruded aluminum parts do not have to undergo oxidation. Manufacturing a range of shock absorbers suspension and damping products for mopeds motorcycles scooters and industrial applications.

GKN Powder Metallurgy is a global engineering and manufacturing partner of metal powders and product solutions for automotive and industrial markets. The companys engineering design and manufacturing process meets major US and European OE automotive manufacturers standards. Package cushioning is used to protect items during shipmentVibration and impact shock during shipment and loadingunloading are controlled by cushioning to reduce the chance of product damage.

Some people like smaller trucks much better mostly because they use less gas and are easier to maneuver. Forging is a simple process that involves pounding squeezing. From the companys use of the finest raw materials to precision-focused manufacturing.

Manufacturing Assembly The landing gear manufacturing involves development of many closed die forgings machined components from ultra-high strength steels titanium and aluminum alloys. Common cold extruded aluminum products include gear blanks shock absorber cylinders fire extinguisher cases and collapsible tubes. Endurance is a leading auto component manufacturer.

New Part of Sale. The importance of quality is at the forefront in the complete design and manufacturing process. We start here in Australia by taking all the vehicle information such as dimensions weights spring rates and suspension geometry as well as the vehicle type and market requirements.

Sala 390mm Shock Absorber Snap Hooks Each End. Lever Type Shock Absorber. KONI is the premier manufacturer of performance and adjustable shocks in the world.

BEN Dobinson from Dobinsons Suspension walked us through the companys manufacturing process. Additionally in most cases the single-wall shock absorber is considerably stronger than the twin-tube shock absorber because they typically use a larger diameter piston. But before we go on our main highlight we would like to give a little overview of shock absorber meaning how does it work and most specially the opportunities ahead of this auto parts.

Koni Adjustable Shock Absorbers. Spax is the one British Company still manufacturing shock absorbers in England that was working with British Car manufacturers in the 1960s. The lever-type shock absorber is of indirect-acting type.

All BP-51 shock absorbers are manufactured in-house by ARB. Kit includes2 Rear 4-Link Mounts5 Rear Shock Mounts3 Upper Front Shock Mounts2 6th Coil Mounts4 Lower front shock Mounts4 Lift Bar linkage Mounts8 New Product Fuel Safe Dirt Late Model Racing Fuel Cell Super tough FIA-FT3 certified Enduro bladder Powder coated black 20 gauge steel container -6 rollover vent valve -8 fuel return Dipstick -10 pickup with side outlet 2. The Factory was a assembly unit from beginning to dispatch by a small groups No supervisor inside the shop floor.

Heat treatment of parts is performed after rough. In order to achieve this significant investment has been made in state of the art machining and hard anodising equipment allowing ARB total control of the process to ensure the highest possible quality. Dobinsons shock absorbers are designed specifically for each vehicle model and application to ensure the.

The companys engineering design and manufacturing process meets major US and European OE automotive manufacturers standards. As the axle moves up and down a double piston arrangement forces the oil through a valve. 23 Nov 21 840 PM AEDT.

Telescopic type shock absorber is of direct-acting type. This article covers the top automotive shock absorber manufacturers list under OEM channel type. Precision tolerances are required for components like actuator cylinder piston shock absorber parts and axle.

It is bolted to the chassis through a lever and link. Cushioning is usually inside a shipping container such as a corrugated boxIt is designed to absorb shock by crushing and deforming and to dampen vibration rather than transmitting the shock and. KONI has taken shock absorber performance and comfort to the next level with patented FSD Frequency Selective Damping technology.

From the companys use of the finest raw materials to precision-focused manufacturing. Telescopic Type Shock Absorber. Spring 2022 Fall 2021 Summer 2021 10 Week Session This course introduces the scientific principles that deal with energy conversion among different forms such as heat work internal electrical and chemical energy.

MEYLE automotive spares over 24000 parts for passenger cars vans and trucks. KONI shocks are made from the highest quality raw materials and machined to the tightest tolerances. 4x4 shock absorber manufacturing process.

In contrast to these conventional shock absorbers the K3 line uses a unique flexible pendulum technology which provides shock absorption only parallel to the desired direction of motion eliminating rotational movement. These special separators serve as a shock absorber to the battery. In one of the Shock Absorber manufacturing Factories where I was on additional responsibility for some months due to different exigencies.

For over 25 years the Arnott family has been the innovator in air suspension replacement products. The physical science of heat and temperature and their relations to energy and work are analyzed on the basis of the four. NEW Chain Blocks Industrial wear safety gear - 9 Start Nationwide Delivery.

These shock absorber types are much more precise at dampening than the standard shock absorber because they are made with considerably more precise standards during the manufacturing process.

Shock Absorber Technologies For Automated Applications

Shock Absorber Wikipedia

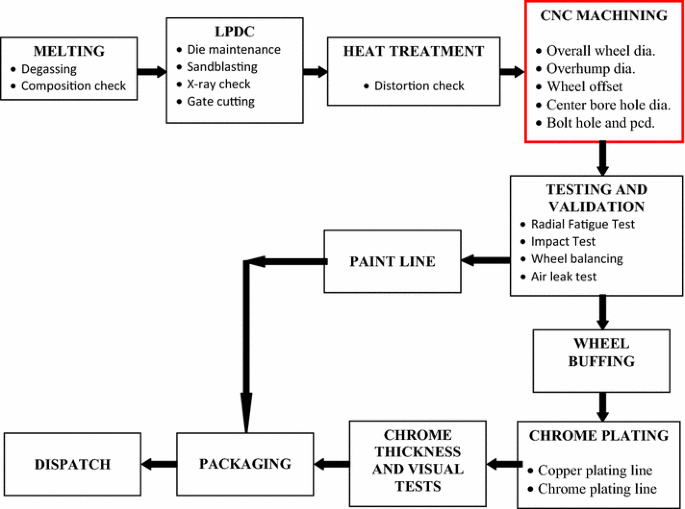

Process Capability Improvement Through Dmaic For Aluminum Alloy Wheel Machining Springerlink

Vehicle Suspension Manufacturers China Customized Products Gold Star Spring

Shock Absorber An Overview Sciencedirect Topics

Greatparts Shock Absorbers Manufacturing Process

P4 Series For Rechargeable Battery Manufacturing Process Fixed Shock Absorber Nck P4 Component Products Ckd Corporation

Differences Benefits Of A Monotube Twintube Shock Absorber Also Info On Inverted Acura Rsx Ilx And Honda Ep3 Forum